Is Carbon Fiber Stronger Than Silicone?

Introduction

When choosing materials, strength often matters most. Carbon fiber and silicone are both popular. They serve different roles. Yet many wonder which one is stronger.

In this article, we will compare carbon fiber and silicone. We will look at their basic properties. Then we will dive into numbers. Finally, we will show real-world uses.

Our goal is to give clear answers. We will use simple sentences. We will include thorough details.

You will learn why carbon fiber is much stronger than silicone. This guide is perfect for engineers, hobbyists, or curious readers.

What Is Carbon Fiber?

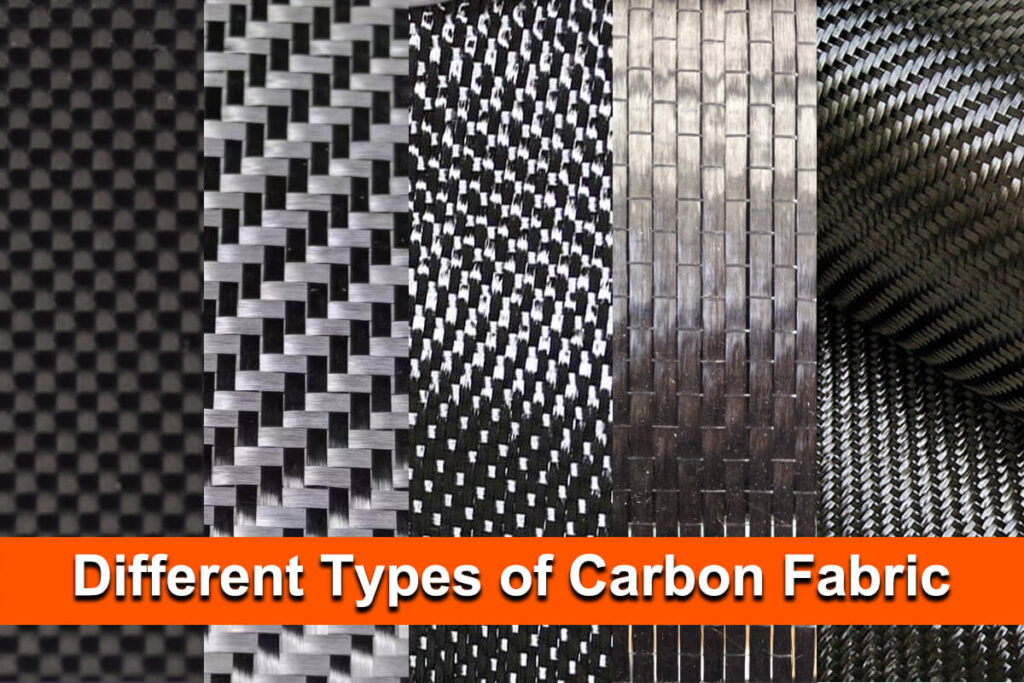

Carbon fiber is made from very thin strands of carbon. These strands are usually woven into a fabric or mixed with a plastic resin.

This mix makes a composite that is both light and stiff.

The fibers are heat-treated under high temperatures. This step turns the fibers into a nearly pure form of carbon.

Carbon fiber has a layered atomic structure. Each layer is a sheet of carbon atoms in a hexagon pattern. These layers bond together tightly.

This gives the fibers high stiffness and strength.

Carbon fiber is used in cars, airplanes, bikes, phone cases, and sports gear because it is very light and strong.

What Is Silicone?

Silicone is a polymer made mainly of silicon, oxygen, carbon, and hydrogen. It is often called silicone rubber or polysiloxane.

Silicone is soft and elastic. It can stretch without breaking. It also handles heat well.

Silicone stays flexible from –100 °C to 300 °C (–150 °F to 570 °F).

Key Mechanical Properties

To compare strength, we look at mechanical properties. Key metrics include:

- Tensile Strength: Force needed to pull until break.

- Young’s Modulus: Stiffness or resistance to stretching.

- Compressive Strength: Force needed to crush.

- Flexural Strength: Resistance to bending.

Carbon fiber scores very high on tensile strength and stiffness. Silicone scores low on these. But silicone has high elasticity and flexibility.

Tensile Strength

- Carbon fiber composites: 3–7 GPa (3,000–7,000 MPa) of tensile strength.

- Pure carbon fiber strands: up to 5,650 MPa in some fibers.

- Silicone rubber: around 5–15 MPa of tensile strength.

Here, 1 GPa equals 1,000 MPa. Carbon fiber is roughly 200 to 1,400 times stronger in tension than silicone.

Young’s Modulus

- Carbon fiber: 200–500 GPa (200,000–500,000 MPa).

- Silicone: around 1–10 MPa (depending on type).

Carbon fiber is dramatically stiffer. It barely bends under force. Silicone bends easily under small loads.

Carbon Fiber VS Silicone: Detailed Strength Comparison

| Property | Carbon Fiber Composite | Silicone Rubber |

|---|---|---|

| Tensile Strength | 3–7 GPa (3,000–7,000 MPa) | 5–15 MPa |

| Young’s Modulus | 200–500 GPa | ~1–10 MPa |

| Elongation at Break | 1–2% | 200–800% |

| Density | 1.6 g/cm³ | 1.0–1.2 g/cm³ |

| Operating Temperature | –200 to 300 °C | –100 to 300 °C |

This table shows that carbon fiber is superior in strength and stiffness. Silicone is superior in flexibility and stretchiness.

Why Carbon Fiber Is So Strong

The strength of carbon fiber comes from its molecular structure. Layers of carbon atoms form graphene sheets. These sheets are tightly bonded.

The manufacturing process pulls the fibers to align the graphene layers. This alignment maximizes strength along the fiber axis.

High-temperature treatment removes non-carbon atoms. This step increases crystallinity.

More crystalline areas mean more strength. The result is a fiber with very high tensile strength and stiffness.

Why Silicone Is Flexible but Weak

Silicone’s backbone has silicon-oxygen bonds. These bonds are longer and more flexible than carbon-carbon bonds.

This makes silicone soft and elastic. Its polymer chains can slide past each other when stretched.

Silicone also contains organic groups attached to its backbone. These groups add flexibility. They prevent the chains from packing tightly.

As a result, silicone cannot resist high tensile or compressive forces.

Real-World Applications

Where Carbon Fiber Shines

- Aerospace: Parts such as wings and fuselage panels benefit from high strength and light weight.

- Automotive: Body panels, drive shafts, and frames use carbon fiber for weight reduction.

- Sports Equipment: Bicycle frames, tennis rackets, golf clubs, and skis need high stiffness and low weight.

- Phone Cases: There are some high-end phone cases are made of carbon fiber. They have better performance than silicone material.

In these uses, strength-to-weight ratio is crucial. Carbon fiber excels here.

Where Silicone Shines

- Seals and Gaskets: Flexibility and heat resistance make silicone perfect for sealing joints.

- Medical Devices: Tubing and implants need biocompatibility and elasticity.

- Cookware: Baking mats and spatulas need food safety and flexibility.

Silicone’s ability to stretch and recover is vital in these roles.

Pros and Cons

Carbon Fiber

Pros

- Extremely high strength-to-weight ratio.

- Very stiff and dimensionally stable.

- Can handle high fatigue loads.

Cons

- Brittle; can crack under impact.

- Expensive materials and processing.

- Hard to recycle.

Silicone

Pros

- Highly flexible and stretchable.

- Excellent thermal stability and chemical resistance.

- Good for food and medical use.

Cons

- Low tensile and compressive strength.

- Wears under high friction or heavy loads.

- Not suitable for structural applications.

Conclusion

Carbon fiber is vastly stronger than silicone. It offers tensile strength in the gigapascal range. Silicone works in the megapascal range.

The two materials serve very different needs.

Use carbon fiber when you need rigidity and strength. Use silicone when you need flexibility and resilience.

Knowing the mechanical limits helps you pick the right material. Always check specific grades and composites.

Manufacturers can tailor both carbon fiber and silicone for niche needs. But in pure strength, carbon fiber wins by a wide margin.